Time is not evenly spaced. How analyze?

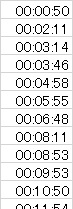

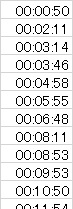

Although it is not exactly evenly spaced, in this case, it may be considered as evenly spaced and analyzed. If you calculate the interval as the time difference, it looks like the figure below, and it is almost 1 minute interval, so you can think of it as 1 minute interval.

Some methods of Time Series Analysis assume that the data table is arranged in the order of time from the top, and that the difference in one row represents the difference in one minute, for example. In the calculation, the method is based on the rules of how to arrange the data without directly dealing with the numbers of time and time.

Is it okay to use a method that assumes equal intervals when the data is known to be as described above? , Is the background of your question.

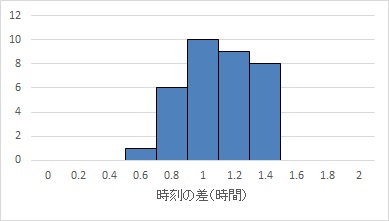

In the case of the graph below, the above idea cannot be used because the intervals are large.

In the case of this example, the value goes up and goes down in one cycle, so it seems that the data is taken from the time when it starts to go up and the recording of the data is stopped when it goes down.

If there is information you want to know during this cycle, you can find out what you want to know even if you analyze it as even intervals .

In the case of this example, for each cycle, there is a method to calculate the time from that time for each cycle, with the time when the data starts to rise as 0. It is a feature amount of "time from the beginning of becoming high". As an application, it is also possible to calculate the time retroactive from the time when it becomes low, and create a feature quantity called "time until it becomes low".

It is a method to cut out "each cycle", but if you calculate the time between cycles without data recording, you can judge that "time is XX or more, cycle break", so use this as a code Create a mechanism to automatically total.

Furthermore, if you use the method of cutting out in cycles, you will be able to create features such as "time to reach the maximum value in each cycle". This is a technique that can be used in the analysis of manufacturing methods in factories.